You will also need to plan your exhaust route. This should include a way to route the exhaust ducting, to mount the fan and power the fan, and to allow for fresh air back into your space.

The best practice is to have as short of a venting run as possible, with no more than two 90-degree bends. We would also recommend placing your exhaust fan near the end of your exhaust tubing – you want to be pulling air out rather than pushing it through the tube. You may need to purchase an extension cable for the exhaust fan and longer exhaust hosing if your setup requires it; These can typically be found at your local hardware store, but contact support@thunderlaser.ca if you are unsure and need assistance.

You can also run a filter box setup that can interface with the machine. Read more in our article below

More information can be found here:

Electrical Install plan:

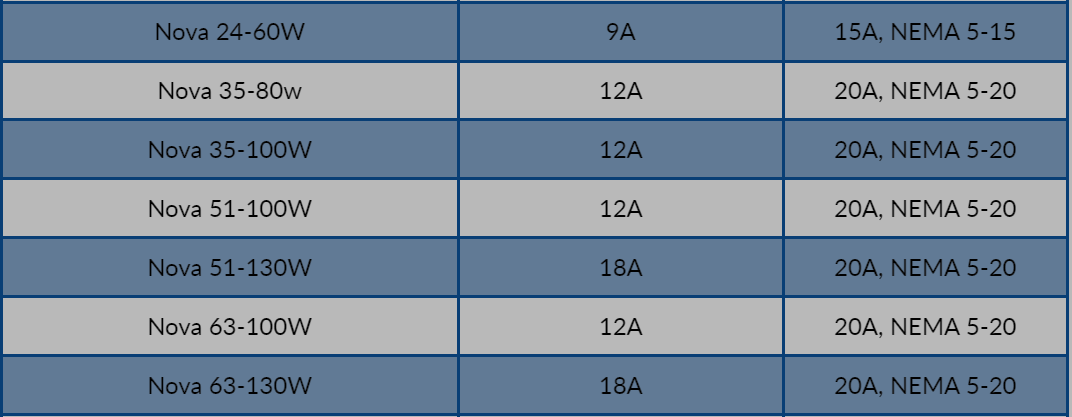

Other than the Nova 24, you will likely need to upgrade your circuit panel to plug in our medium and larger sized Nova machines. The receptacle should be placed such that the machine can be plugged into it without the use of an extension cord.

Let your electrician know that the required connection for Nova 35, 51 and 63 is 120v 20amp. Thunder Lasers do not operate and will be damaged is you use 220v.

From this dedicated 120V circuit, all the peripherals – the air compressor, chiller, and exhaust – will plug into the back of the laser machine, which will control the main power for all of these devices.

More information can be found about the Electrical requirements for your machine here:

Thunder Laser Main Power Requirements

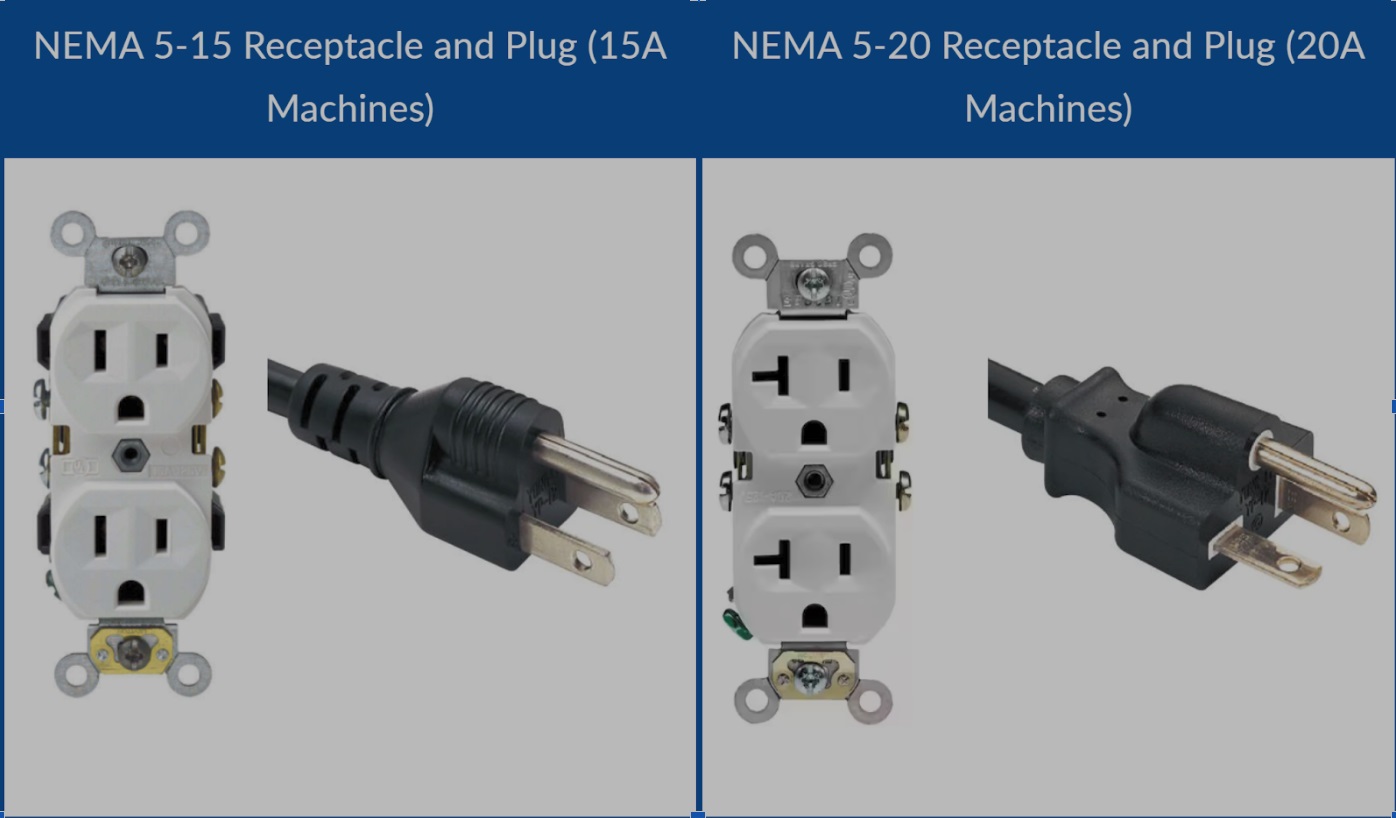

Understanding 20A Plug – 15A Receptacle Incompatibility