Choosing a Machine. Size and Power.

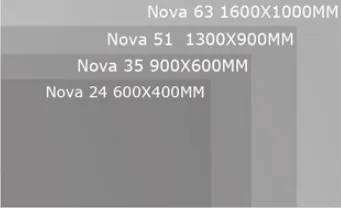

The machines’ bed size will determine how big of a piece of material you can fit in the machine to cut or engrave. A bigger bed will allow you to cut or engrave larger pieces and even if you're doing something small, like laser cut jewellery, a bigger bed will allow you to cut out multiple pieces at once rather than one at a time. Some machines have a fixed bed and some have a bed that can go up and down. A bed that goes up and down allows you to engrave different sized objects. The cutting depth doesn’t change but if you want to engrave a logo or a design on a leather shoe rather than on a flat piece of leather, having a bed that you can lower to get the shoe in the machine is important.

Depending on the type of material, a different laser power have better results. For example, engraving paper usually requires much less power than engraving wood. With acrylic, a uniform, light engraving can be created using a low power laser. And when processing engraving materials, higher power allows faster work. The laser power can be easily regulated by the software, however the maximum power depends on the hardware. A laser machine with high laser power has more flexibility as it allows you to process many different types of material. The table shows an overview of the required different powers for maximum thickness:

| Power |

40W |

60W |

80W |

100W |

130W |

| Wood |

5mm |

8mm |

10.0mm |

15.0mm |

20.0mm |

| Acrylic |

10.0mm |

15.0mm |

20.0mm |

20.0mm |

25.0mm |

.png) International

International

United States

United States Brasil

Brasil Canada

Canada

Česká

Česká

Ελλάδα

Ελλάδα

Polska

Polska Ireland

Ireland

Portugal

Portugal

Lietuva

Lietuva

Россия

Россия

Deutschland

Deutschland

Britain

Britain

Україна

Україна

France

France

Sverige

Sverige

한국

한국

中国

中国

ประเทศไทย

ประเทศไทย

香港

香港

Israel

Israel

臺灣

臺灣

India

India

Australia

Australia

New Zealand

New Zealand

South Africa

South Africa